|

| May 10, 2016 | Volume 12 Issue 18 |

Designfax weekly eMagazine

Archives

Partners

Manufacturing Center

Product Spotlight

Modern Applications News

Metalworking Ideas For

Today's Job Shops

Tooling and Production

Strategies for large

metalworking plants

Engineer's Toolbox:

Million-pound weight stack restored

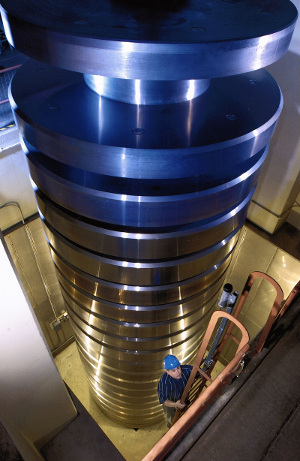

NIST's million-pound deadweight machine fully assembled. [All images courtesy: NIST]

It's official. The National Institute of Standards and Technology's (NIST) 4.45-million-newton (equivalent to 1 million lbf) deadweight machine -- the largest in the world -- is back in one piece after a colossal 16-month effort to overhaul the system for the first time after it was built 50 years ago.

The year-and-a-half-long saga involved dismantling, cleaning, restoring, and recalibrating about half of the stainless steel discs in the three-story stack of weights. It marked the first time the device had been taken apart since its original installation in 1965.

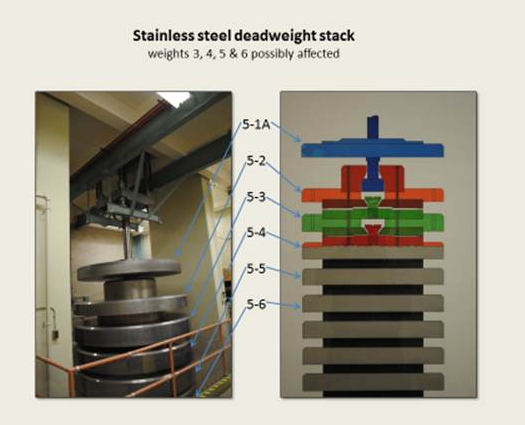

The surfaces of a half-dozen components of the deadweight apparatus underwent minor machining at NIST and by a company offsite to permit more free operation at those interfaces. Pieces that were sent offsite returned to NIST in June fully restored. Dismantling the weight stack took several weeks, because each piece had to be unbolted and carefully lifted with a series of cranes.

"This was an extremely complicated, time-consuming, labor-intensive operation with major risks and decisions at every turn," says Mass and Force Group Leader Zeina Kubarych. "From planning to teamwork and coordination, to risk mitigation and execution, this was a remarkable achievement and a success to be proud of.

"Perfectly orchestrated restoration of one of NIST's and the world's metrology treasures with no injury to personnel and no damage to property -- a big weight off my shoulders!"

An offshoot of the project is that researchers are modeling the stack to get insight into the deflections occurring where the stresses are highest.

BEFORE (left): Restoration was required to repair galling near the bottom of the conical "donut hole" in the middle of this weight. AFTER: The shining restored surface of one of the weights sent offsite for minor machining.

Thousands of measurements through many force calibrations have been performed over the lifespan of the 4.45-MN deadweight machine. Previously, the machine was the centerpiece of two multi-year, international key comparisons that assured comparability of measurements throughout the world for large primary forces. It is an international resource that has disseminated force units to a worldwide customer base since its inception, and it is a source of U.S. national pride in the world of metrology.

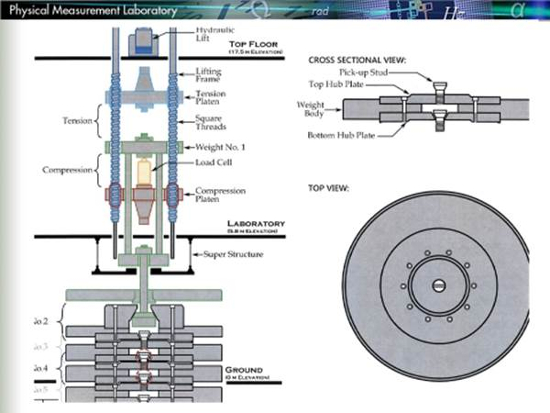

The 4.45-MN deadweight system consists of a calibrated "T-shaped" lifting frame and a stack of 19 stainless steel discs.

How does it work?

"This largest of NIST's six deadweight machines realizes or generates downward force by hanging well-characterized stainless steel weights (the forces generated are static, hence the term deadweight) in the gravity field with a required air buoyancy correction applied, thus producing a net vertical force vector of 4.45 MN (1,000,000 lbf) when all 20 force increments are applied," explains Rick Seifarth, Mass and Force Group, NIST. "The first 222.4-kN (50,000-lbf) increment is comprised of the initial frame assembly. The next 19 nearly identical 222.4-kN (50,000-lbf) increments are the 3.1-m (10-ft) diameter weights."

And each disc is not a solid piece.

"The main 3.1-m diameter weights have four main parts: the upper center hub plate (1.83 m diameter), the main weight body (3.1 m diameter), the bottom center hub plate (1.83 m diameter), and the center lifting stud," says Seifarth. "These four parts, along with the 10 socket-head cap screws that bolt each 'weight sandwich' together, have a combined mass of approximately 50,036.27 lb. Given our local acceleration of gravity and the air buoyancy correction, that amount of mass object is required to produce 50,000 lbf of net vertical force as a vector coincident with the gravitational vector."

"Four of the 1.83-m diameter bottom center hubs were sent out to a large commercial shop for machining due to their size," adds Seifarth. "Two of the center studs were remachined by our onsite metal shop."

The final task before reassembly was recalibration of the 50,000-lb discs.

A restored component of the million-pound deadweight machine being returned to NIST in June.

Lab officials from NIST visited the machine this month, just a few days after the last bolts were torque-wrenched into place. They received a tour of the facility, which includes a control room above the weight stack and a hydraulic ram that moves the weights up and down.

At the event, Carl Williams, the Deputy Director of NIST's Physical Measurement Laboratory (PML), introduced and congratulated project leader Rick Seifarth, whose team orchestrated the refurbishment process and performed the calibrations of the larger masses. Seifarth's team includes PML's Kevin Chesnutwood and Sam Ho.

PML restoration team and leadership in front of the newly refurbished million-pound weight stack. From left to right: Project Leader Rick Seifarth, Sam Ho, Kevin Chesnutwood, and Mass and Force Group Leader Zeina Kubarych.

Force metrology customers who rely on this unique device include U.S. aerospace manufacturers, U.S. military laboratories, and several top-end commercial force calibration labs.

NIST is planning a grand gala celebration in June to mark the opening of the million-pound deadweight machine, which is scheduled to take place once the facility is back online and open for business.

Source: NIST

Published May 2016

Rate this article

View our terms of use and privacy policy